(continued from previous page)

Plastic containers and silica gel packets are good tricks for keeping drills, end mills, taps, and small-to-medium size machining accessories free from rust. However, larger metal machining tools, such as mills and lathes are constantly exposed to moisture in the air.

The most common technique for preventing rust on a lathe bed or milling machine table is to make sure the surface is coated with light machining oil or other rust preventative. However, some machinists go the extra mile by running an dehumidifying appliance nearby.

Dehumidifier with plastic container mounted on top and foam tiles underneath.

Unfortunately, dehumidifiers can be expensive to buy, costly to run, and noisy. The noise on my dehumidifier model can be heard on the floor above.

In a vain attempt to quiet the dehumidifier, I placed kids foam alphabet mats underneath. It reduces the dehumidifier noise a little bit, but not enough to recommend it as a solution.

At some point it occurred to me that the vibrational energy might be put to good use in sorting or compacting my scrap material. I know this sounds weird, but everyone has noticed the signs that say “Contents may have settled during shipment”. Furthermore, I hypothesized that attaching metal scrap would consume some of the waste energy and reduce noise.

Brass shavings sifted by vibration. The largest strands are on top and the smallest particles fell to the bottom.

I screwed a plastic tub on top of the dehumidifier. After every project, I collected brass shavings and put them into a recycled plastic jar. I then placed the jar into the tub.

Over a series of months, the brass remnants did indeed sort from largest to smallest, but not as well as I had hoped. Perhaps larger waveform motion is required, like in the trunk of a car? Also, I didn’t notice a difference in dehumidifier noise output. So, that experiment was pretty much a failure.

However, I may still use the apparatus for jars where materials are being soaked in WD-40 to be loosened. And, the vibrations might improve PCB etching time.

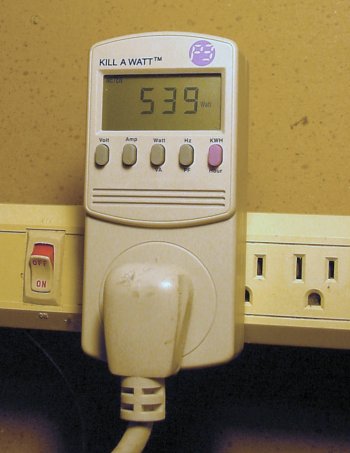

P3 Kill-A-Watt meter indicates the floor-height portable dehumidifier uses up to half a kilowatt of power.

Although I do think the dehumidifier appliance makes a difference in the ambient humidity, it is expense to run. I plugged the dehumidifier into an off-the-shelf P3 Kill-A-Watt monitor. It says the dehumidifier uses 539 watts.

If my basement dehumidifier is constantly running, that will cost:

539 watts / 1000 hours = 0.539 kilowatt hours (kWh) of power.

0.539 kWh * 24 hours in a day * 365 days in a year = 4721 kWh per year.

4721 kWh * $0.07 average cost per kWh = $330 to run full time per year.

The dehumidifier doesn’t run full time during the winter. And, there are less-dry settings available. However, this calculation shows that a dehumidifier is expensive to run, even though if it is an energy-star appliance.

I guess I have to consider whether or not it is adequate to use just the plastic containers, silica gel desiccant packs, and oil coated tools. At $330 a year, I could buy a lot of new tools.

If all of this advice comes too late for one of your precious tools, there is a technique for removing rust using electricity.